At FloPlast, not only do they send zero waste to landfill, but they have also found a sustainable way to reuse the waste products generated from their Injection Moulding process.

All waste materials are separated and sorted into colour and material type by our recycling team, they are then loaded into granulators, where the plastic is ground into small chips. These chips are mixed with the equivalent virgin material and fed back through the system to manufacture FloPlast products.

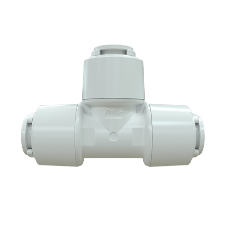

All products are put through a stringent testing process, to ensure FloPlast maintain their high quality standards

Check out the video to see this cycle in action.

Re-grind, Recycle, Reuse: Manufacturing Zero Waste Injection Moulded Products

| T | +44 (0)1795 431731 |

|---|---|

| E | technical@floplast.co.uk |

| W | Visit FloPlast Ltd's website |

| Eurolink Business Park, Castle Road, Sittingbourne, Kent, ME10 3FP |